Water electrolyzed system slideshare

Table of Contents

Table of Contents

When it comes to food processing plants, ensuring that they are thoroughly and effectively cleaned is essential to prevent contamination and maintain high levels of hygiene. One cleaning method that is gaining popularity in recent years is electrolyzed water cleaning, which has been proven to be effective in killing bacteria and viruses, and is also environmentally friendly. In this article, we will explore the benefits of electrolyzed water cleaning for food processing plants.

Pain Points of Food Processing Plant Cleaning

Cleaning food processing plants is no easy task. The equipment, floors, and walls must be cleaned thoroughly to ensure that all bacteria and other contaminants are removed. Traditional cleaning methods using harsh chemicals are not only less effective, but they can also be harmful to workers and the environment. Additionally, the use of chemicals in food processing plants can leave behind residues that are difficult to remove, leading to further contamination.

What is Electrolyzed Water Cleaning?

Electrolyzed water cleaning is a natural, eco-friendly method of cleaning and disinfecting surfaces. The process involves running an electrical current through a solution of water and salt, which creates two byproducts: sodium hydroxide (NaOH) and hypochlorous acid (HOCl). NaOH is a powerful cleaner and degreaser, while HOCl is a natural disinfectant that is effective against bacteria, viruses, and other contaminants.

Benefits of Electrolyzed Water Cleaning for Food Processing Plants

Electrolyzed water cleaning offers numerous benefits for food processing plants, including:

- Effective cleaning and disinfection of surfaces

- Elimination of harmful chemicals

- Environmentally friendly

- Cost-effective

- Reduction in water usage

My Personal Experience with Electrolyzed Water Cleaning

At my previous job, I worked at a food processing plant that was struggling with maintaining high levels of cleanliness. They were using traditional cleaning methods that were ineffective and time-consuming. However, after implementing electrolyzed water cleaning, we noticed a significant improvement in the cleanliness of the plant, and it was also reassuring to know that we were using a natural and eco-friendly cleaning method.

Implementing Electrolyzed Water Cleaning in Your Food Processing Plant

Implementing Electrolyzed Water Cleaning in Your Food Processing Plant

If you’re interested in implementing electrolyzed water cleaning in your food processing plant, it’s essential to work with an experienced and reputable cleaning company. The cleaning company can help you to evaluate your current cleaning program and determine the most effective plan for implementing electrolyzed water cleaning.

### How Electrolyzed Water Cleaning Works

### How Electrolyzed Water Cleaning Works

The process of electrolyzed water cleaning involves:

- Diluting the saltwater solution to the desired concentration

- Running an electrical current through the solution to create the cleaning and disinfecting agents

- Applying the solution to surfaces using a spray bottle, mop, or other cleaning equipment

- Rinsing the surfaces with clean water to remove any residue

#### The Importance of Regular Cleaning and Disinfection

#### The Importance of Regular Cleaning and Disinfection

Regular cleaning and disinfection of food processing plants are essential to preventing contamination and ensuring that products meet safety standards. Electrolyzed water cleaning provides an effective and eco-friendly cleaning option that can help to maintain high levels of hygiene and safety in food processing plants.

Question and Answer

Question and Answer

Q: Is electrolyzed water cleaning safe for food processing plants?

A: Yes, electrolyzed water cleaning is safe for food processing plants. It is a natural, eco-friendly cleaning method that does not leave behind harmful residues or chemicals.

Q: Does electrolyzed water cleaning require special equipment?

A: Yes, electrolyzed water cleaning requires specialized equipment to create the cleaning and disinfecting agents. However, many cleaning companies offer this service and can provide the necessary equipment.

Q: Can electrolyzed water cleaning be used on all surfaces?

A: Yes, electrolyzed water cleaning can be used on most surfaces, including stainless steel, plastic, and concrete. However, it may not be suitable for certain surfaces, such as porous surfaces that can absorb the cleaning solution.

Q: How often should food processing plants be cleaned using electrolyzed water cleaning?

A: The frequency of cleaning using electrolyzed water cleaning will depend on the specific needs of the food processing plant. However, it’s recommended to clean and disinfect surfaces daily, or more frequently if needed.

Conclusion of Electrolyzed Water Cleaning for Food Processing Plants

Electrolyzed water cleaning offers numerous benefits for food processing plants in terms of effective cleaning and disinfection, reduced environmental impact, and cost-effectiveness. If you’re interested in implementing electrolyzed water cleaning in your food processing plant, it’s essential to work with an experienced and reputable cleaning company that can help you to evaluate your current cleaning program and determine the most effective plan for implementing electrolyzed water cleaning.

Gallery

Water Sanitizer A Safer Solution For Cleaning Kills Bacteria Naturally

Photo Credit by: bing.com / water solution electrolyzed cleaning sanitizing process sanitizer eo safer natural eow activated naturally kills bacteria hospitals retail hotels food great

Hypochlorous Acid AKA Electrolyzed Water— Could Be Positioned To Upend

Photo Credit by: bing.com / electrolyzed hypochlorous ions disinfectant grower passed surface disrupt disinfectants makers upend positioned aka

Electrolyzed Water For Cleaning & Disinfecting: How It Works - Force Of

Photo Credit by: bing.com / electrolyzed disinfecting forceofnatureclean

Electrolyzed Water System

Photo Credit by: bing.com / water electrolyzed system slideshare

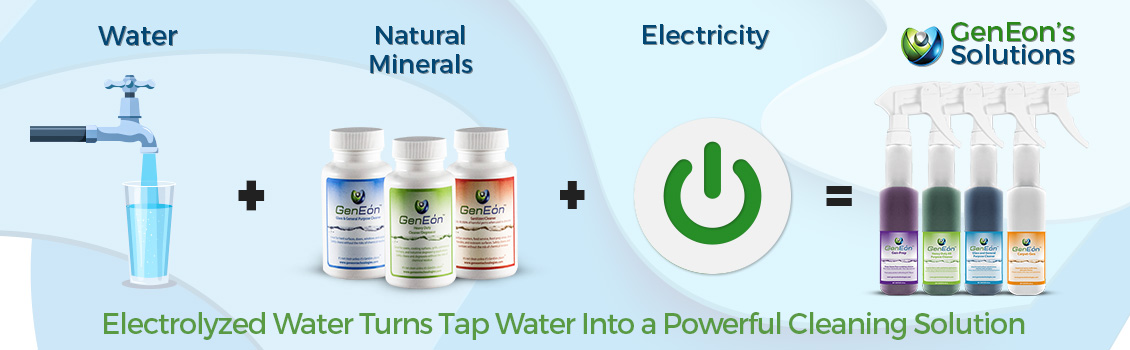

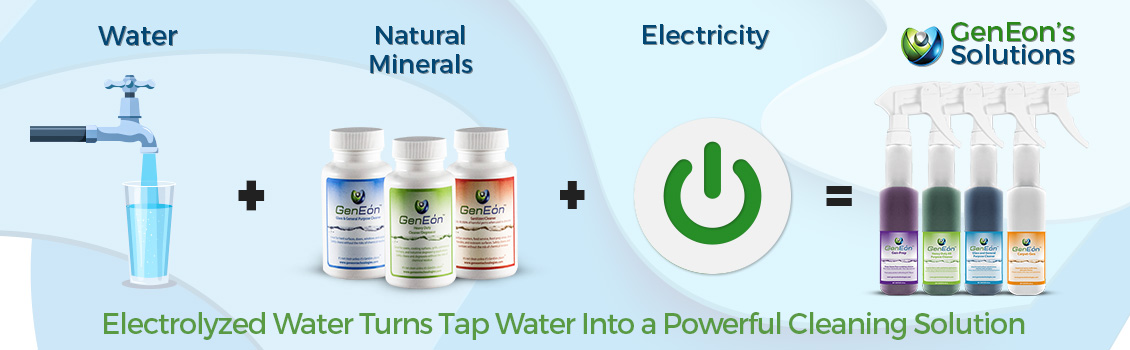

Electrolyzed Disinfectant Cleaning System - GenEon Technologies

Photo Credit by: bing.com / water electrolyzed cleaning cleaner geneon system disinfectant